PRODUCTS

Shell quicklime

Shell quicklime

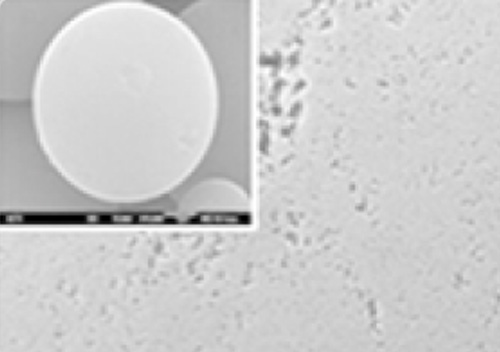

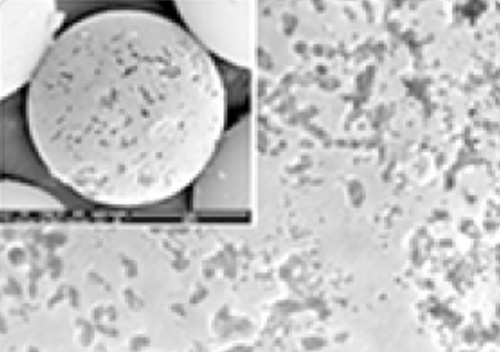

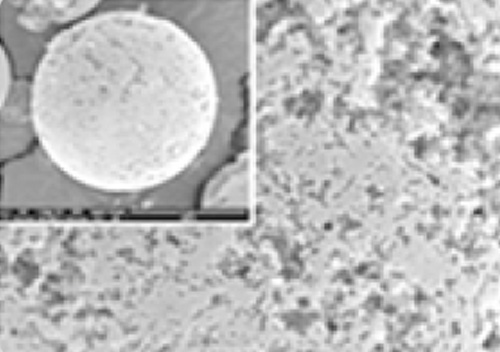

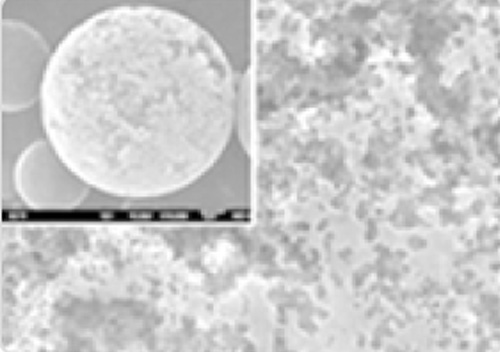

A quicklime product made by recycling shells such as clam shells or

oyster shells from sheep shells and baking them at high temperature.

Shell quicklime

A quicklime product made by recycling shells such as clam shells or oyster shells from sheep shells and baking them at high temperature.

- This product is manufactured using M.C.S.K. The firing state can be freely adjusted.

- By firing at high temperature, the size of the fired ore particles varies (20~150mm)

- Reduce operating and management costs by increasing reaction tank processing capacity

Features

- This product is manufactured using M.C.S.K. The firing state can be freely adjusted.

- By firing at high temperature, the size of the fired ore particles varies (20~150mm)

- Reduce operating and management costs by increasing reaction tank processing capacity

Specification

| Name | Chemical composition (%, wt) | Physical ingredients | Note | |||||

|---|---|---|---|---|---|---|---|---|

| CaO | MgO | SiO₂ | Fe₂O₃ | AI₂O₃ | Particle size | Weight | ||

| BCS6134-2SP | 97.8 | 1.4 | 0.2 | 0.04 | 0.1 | <0.8mm, >60% | ||

| BCS0024-275S | 92 | 1.7 | 2 | 0.5 | 0.5 | <1.2mm, >70% | ||

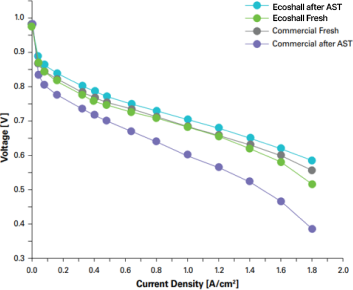

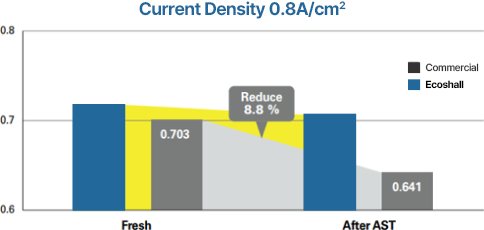

PEMFC_Accelerated Stress Test (AST)

AF Anaerobic Digestion Technology

Rotary Dryer

Dry raw materials using

rotary kiln waste heat

Rotary Kiln

Using C.O.G. as a heat source,

raw materials are fired in a Rotary Kiln.

Rotary Cooler

Cool the fired product using

indirect cooling in a rotary cooler.

Hammer Crusher

Crush the product to

2.8mm or less using a crusher