TONGYEONG RESOURCE CENTER

Tongyeong Shell Recycling Center

TONGYEONG RESOURCE CENTER

Tongyeong Shell Recycling Center

By turning discarded oyster shells into desulfurizing agents and construction materials, we help solve environmental problems and contribute to a sustainable resource cycle.

TONGYEONG RESOURCE CENTER

Tongyeong Shell Recycling Center

By turning discarded oyster shells into desulfurizing agents and construction materials, we help solve environmental problems and contribute to a sustainable resource cycle.

- Processing Capacity: 300 tons per day, up to 80,000 tons annually

- Products: CaO, fertilizers, recycled goods

- Operators: Ecoshell | Techcross | Dongsung Engineering

Main Facilities Configuration

Washing and Drying System

Primary Washer

High-temperature Dryer

Salt Removal & Sterilization

Calcination

System

Calcination Kiln

Fuel System

with Heat Recovery Unit

Crushing and Screening System

Hammer & Ball Mills

Classifier, Dust Collector

Particle Control Automation

Environment Control

Solids Recovery Unit

Deodorizer & Dust Collector

Soundproof System

Benefits & Advantages

Site & Facilities

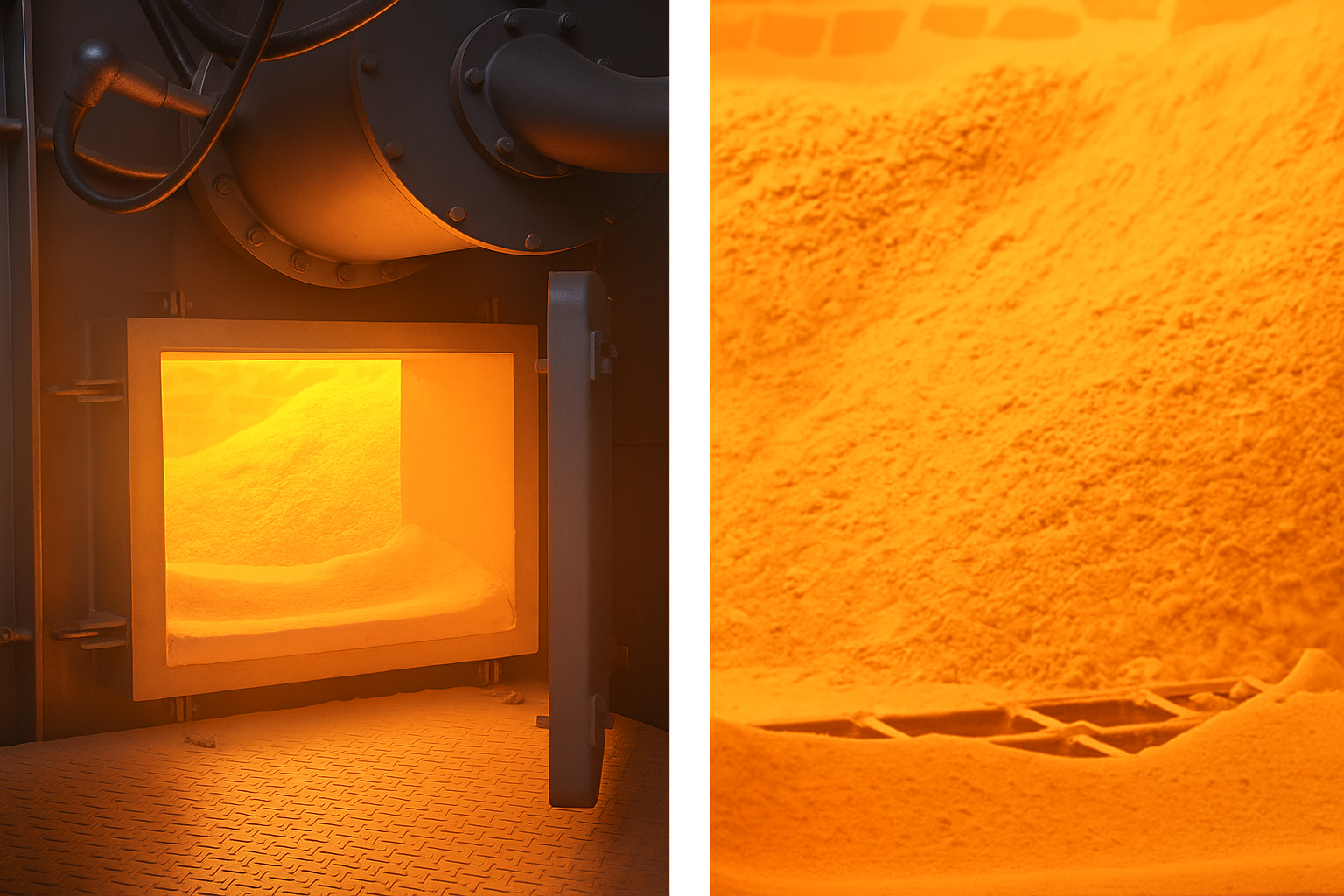

Oyster Shell Calcination Process

Marine Resource Valorization Tech

- Calcined at 1,000°C+ to remove toxins and stabilize shells

- High-temp calcination removes pathogens and impurities

- Calcined shells become calcium-rich material

Oyster shells, once treated as marine waste, are transformed into eco-friendly resources through high-temperature calcination.

This process not only eliminates waste but also adds value by converting it into industrial-grade material, paving the way for applications such as fertilizers, livestock feed additives, and sustainable materials.

Product Specifications

| Product Name | Product Image | Processing Temperature | Purity |

|---|---|---|---|

| Dried Shell-derived CaCO₃ |  |

300~400℃ | CaCO₃ ≥ 95% |

| Shell Quicklime |  |

900~1200℃ | CaO ≥ 90% |